Remote monitoring system “Orion Pulsar” is a software system based on many related software services, that may be used for remote control and monitoring of “Orion” VSD.

VSD connects remotely via installed GPRS-modem. The modem can operate with any mobile operator (activated GPRS-internet service needed). VSD is connected with the server via modem. Server is used for collecting data and sending commands to VSD.

The system provides real time access to VDS’s connected to server. User can be logged in on any mobile devices (smartphone, tablet, laptop or PC) using only web browser.

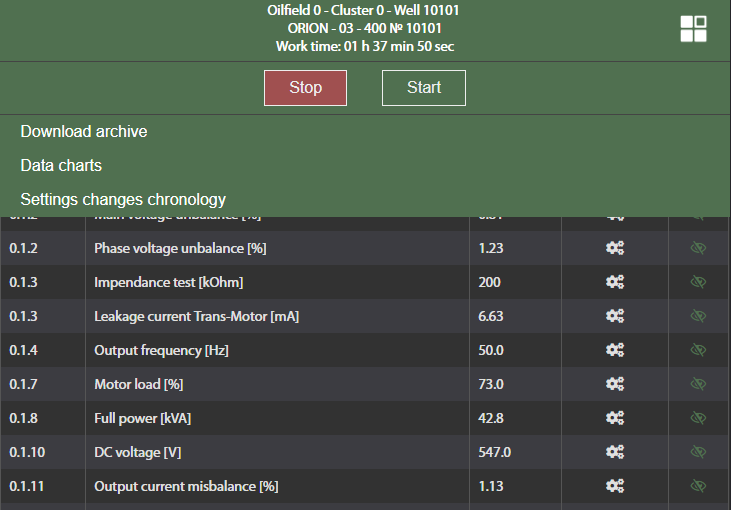

The remote control system provides:- Remote start and stop of VSD;

- View of current operation parameters in table or graphic form;

- Monitor of current settings;

- VSD work mode control by changing settings;

- Work history download;

- Notifications about stops and their reasons;

- Geolocation of the VSD;

- Parameters tracking within user-defined ranges;

- Monitoring of multiple VSD’s from one location;

- Current flow rate by means of “program flowmeter”;

To ensure information security, the “Orion Pulsar” system provides:

- Secure connection based on SSL technologies;

- Login to the “Orion Pulsar” service with personal login and password;

- Connection only to VSD accessible for the user;

- Flexible modification of access for different users.

“Complete access” to current VSD allows user to perform Stop/Start, change settings. These operations can not be performed with “View-only” access.

The user account can be blocked by administrator if needed. In this case this user won’t be able to log into system. Creation of new users, assignment of user roles, allowed VSD, can be carried out by user with administrative role. Login to administrator account and temporary password are provided to the Client during registration in the system.

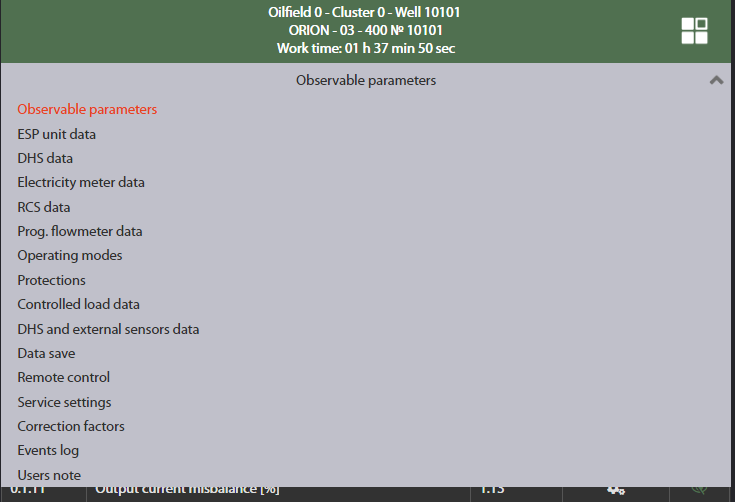

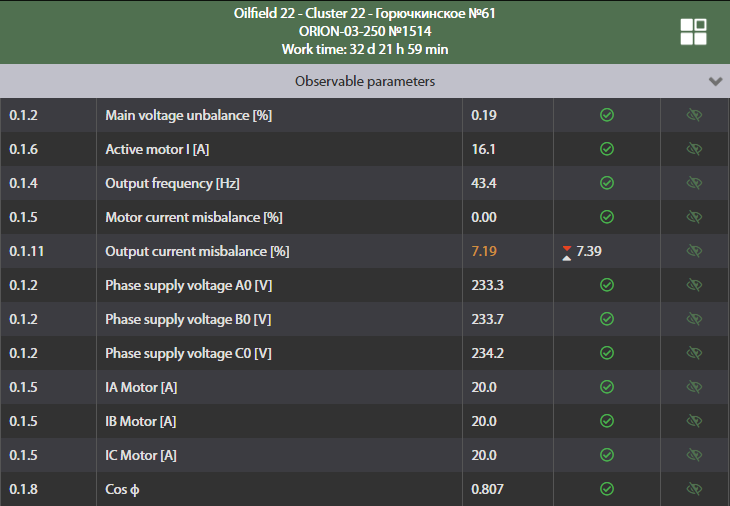

Control panel duplicates VSD controller menu and allows to control VSD in real time. Following options are displayed on the control panel:

- VSD state and duration of the state

- Observable parameters

- Extreme points for out of range parameters

- Current VSD parameters

- Settings that can be changed in real time

- Active protections list (in Stop state)

- Stop/Start VSD buttons

- Charts interface view buttons

- Chronology of recent events

- User notes on current VSD

Orion Pulsar allows to make following VSD data analysis of the logged data:

- Important events (start, stop, protection etc.)

- Current settings in VSD controller

- DHS, electricity meter, analog inputs and power supply data log

- VSD settings history log

- Currents log

- Issues log

- Electricity meter log

Data can be systematized and reviewed in text or graphic form (e.g. diagrams based on log data).

“Orion Pulsar” system can also evaluate the current flowrate using indirectly determination according to the operating parameters of the VDS and DHS. This feature is implemented in the "Program Flowmeter" (“Prog. flowmeter data" tab on the control panel of the main window of "Orion Pulsar").

The production rate (debit) of the well is determined by integrating the flow rate over a given time interval of the VSD. In the subgroup “Prog. flowmeter data” of the VSD tab, the following parameters are displayed:

Debit, last day [m3] - parameter that displays the estimated full day production rate, the value is updated at 0 hours 0 min by the clock of the VSD controller

Debit, current day [m3] - A parameter that displays the estimated running total of current day production rate at the moment. At 0 hours and 0 minutes by VSD controller the parameter is reset to zero with the transfer of data to the Debit, last day.;

Debit, set period [m3] - A parameter that displays the estimated production rate for a given period of time (date, hours and minutes for the beginning and end of the period).

Before its first start-up at a new well, the “program flowmeter” must be adjusted to the characteristics of the pump used and then, during operation, periodically adjusted to take into possible changes of external factors of the pump characteristics.

The use of “Orion Pulsar” may change operation of ESP to fully remote. That opens up additional opportunities to increase the efficiency of fluid production, such as:

- Operation monitoring of the VSD on any device with a web browser;

- Remote control of the VSD of ramping up well;

- Reducing the time of bringing wells to maximum debit;

- Reducing the number and duration of stops due to prompt response to condition of the ESP according to information from the “Orion Pulsar” emergency situations alert system;

- Reducing labor costs for manual control directly at the wells;

- Reducing the number of issues by setting up pre-emergency alerts;

- Monitoring of the current flow rate at the wells using the "Program flowmeter".